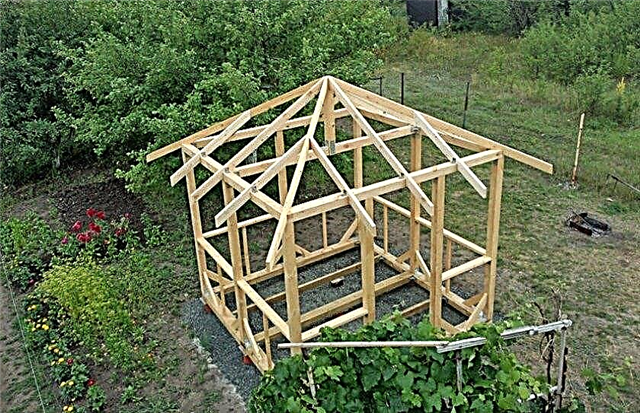

Summer is an ideal time to erect a summer pavilion for relaxation in the garden. A place where you can read a book, have dinner in the family circle and make friends. This article is about how to build a small enclosed arbor from a tree with an area of 4 × 4. It will give step-by-step instructions for the work.

Preparation for construction

In order for the work to go quickly and the result to be satisfactory, the owner of the plot needs to take care in advance of acquiring the right amount of materials. It is also very important to carry out preliminary preparation of the site on which it is planned to erect a gazebo. All stages of construction should be carried out sequentially, one after another, which will ensure the proper quality of the building being constructed.

Did you know? There are a large number of varieties of summer garden buildings, not only open and closed arbors, but also pergolas, benches and swings under a canopy. All of them are intended for recreation of people in nature.

Tools and materials necessary for work:

- grinder, chainsaw, screwdriver, plane;

- hammer, bolts, nuts, steel anchors, nails, roof self-tapping screws;

- water level, measuring tape, corner, chalk;

- antiseptic (stain, impregnation), varnish or paint, brush;

- material for the roof: sheets of particleboard, ondulin, metal or slate;

- liquid bitumen or roofing material;

- wooden boards (4 cm thick) and timber (15 by 15 cm).

Choosing a place and material

Choosing a location for the summer pavilion is a key issue, as it is the most visited place in the summer garden. It is important to decide what it will be used for and what functions to perform. For a passive rest, a quiet and peaceful place is suitable - preferably in the far zone of the site, away from the entrance gate and the street. Architects advise building a gazebo in the immediate vicinity of the house in a similar style. This also applies to the materials from which it will be made.

Important! Floor boards cannot be placed directly on the ground, it is necessary to provide for isolation from exposure to dampness. Neglect of these requirements will lead to the fact that the building will quickly begin to rot and become unusable.

If the site is small and closely adjacent to neighboring households, if possible, try not to place such a structure near a boundary fence. It may happen that the neighbors will interfere with the rest or, conversely, the owners of this site will make too much noise during friendly gatherings.

This building is perfect for outdoor dining or a large party. It would be nice to choose a location close enough to the house so that it would not be burdensome to carry dishes with refreshments. It is also wonderful when the summer house is surrounded on several sides by lush vegetation. This to some extent contributes to additional isolation from prying eyes and gives owners more freedom in the daily use of the room.

In addition, it is worth building a gazebo away from the garage, trash can and septic tank so that no noise or unpleasant odor spoils your vacation.

In addition, it is worth building a gazebo away from the garage, trash can and septic tank so that no noise or unpleasant odor spoils your vacation.

The most popular are the pavilions of pine, spruce, less often of larch or oak. A gazebo made of wood (plank, timber or lining) looks very good surrounded by garden greenery, but its protection should be regularly taken care of. The wooden structure is not allowed to be installed directly on the ground, and the fastening elements must be made of stainless metal.

A wooden 4 by 4 gazebo should have limited contact with the ground, it must be installed on concrete blocks or a brick (stone) foundation. Such protection is sufficient so that the structure does not absorb soil moisture. In addition to dampness, it is threatened by pests (for example, bark beetles and woodworms), fungi and acid rain. Effective prevention can be periodic updating of the outer coating (varnish, paint), as well as the use of impregnating and protective fluids.

Design

Having a private house with a garden, it is worth using all its advantages, one of which can be a gazebo. In summer, this is the place where owners spend most of their free time. Already at the stage of construction or buying a house, the owners should think about how the site will look and whether such an object is needed there. Its location and size are crucial, since an unsuccessful plan can make the summer pavilion a little-visited, useless room.

In the free access of the World Wide Web, you can choose many interesting projects for the construction of arbors 4 × 4. Each of them has its own advantages. The task of the home master is to choose a scheme that would fully meet the needs of households.Did you know? On the Internet you can find unusual projects of garden gazebos, the building material for which are empty plastic bottles from under the water and other drinks with a capacity of 1.5 and 2 liters.

Construction process

The first practical action should be the leveling and strengthening of the surface of the site on which the installation of the summer pavilion is planned. You need to choose the best place, and then remove all the stones, thick wood roots and debris. It is recommended to remove the top layer of fertile soil, replacing it with a mixture of sand and cement, which will help to further strengthen the base.

Having leveled the site, plan the territory to accommodate the future design. Designate all corners of the object. Since the structure will be square, marking is quite simple. The location of the corners of the walls should be fixed with pegs that drive into the ground. Between them pull a rope that outlines the perimeter of the structure.

Foundation

If the owner wants to achieve greater reliability of the foundation, he can make it in the form of a continuous concrete platform. To do this, you need to dig a pit. Along the perimeter of the future building, enclose the side surfaces with the formwork of the boards. To build it, wooden stakes are driven into the corners of the pit, a little more than the recess in height. The space between them is “sewn up” with boards placed “on the edge”.

A sand pillow up to 10 cm deep is laid at the bottom of the pit, then gravel of fine or medium fractions is poured, and then it is poured with concrete mixture. Before the mixture solidifies, the ends of the metal anchors are immersed in it (one under each column), which will be used for the installation of load-bearing racks. After the cementing of the cement monolith, the formwork is no longer needed, and it is disassembled. The existing lateral cracks between the soil and the foundation are covered with sand or soil and compacted tightly.Important! The easiest solution is to erect a gazebo without a foundation on supports standing on the ground surface. Keep in mind that this method of fixing the base is absolutely unstable to gales.

Another option: strip foundation. For its manufacture, a trench is dug with a depth of 70 cm and a width of 50 cm along the entire perimeter of the gazebo. Further, all actions are identical to those performed in the manufacture of a continuous concrete site, but with minor amendments. The formwork will have not one, two opposite walls of boards as boards for cement pouring. Before the cement begins to harden, the ends of the metal anchors are immersed in it through the distance indicated in the project drawing (one for each rack of the above-ground structure), which will be further used when installing the arbor frame.

Did you know? Japanese researchers have determined that during natural disasters, wooden buildings retain their structure better than other structures made of other materials.

But usually such light constructions do not require full concreting as a basis. This means that it is not necessary to make a solid or strip foundation around the entire perimeter of the structure. There will be enough small individual foundations for each support pillar of the elevated frame (their number is indicated on the drawing). To make them, it is enough to dig in the places indicated on the plan, recesses in the soil with a width of about 50 cm and a depth of at least 70 cm. After that, each pit is covered with gravel and poured to the top with concrete mixture.

Bottom and floor installation

The lower side beams of the frame fasten the entire structure and take on the main load of the weight of the pavilion with an area of 4 × 4, including the roof. Such a harness is placed horizontally at a height of 80–90 cm from the foundation line between the frame posts installed on the anchor and is fixed with bolts. An identical operation is carried out in the upper part of the wall frame, retreating 80–90 cm from the future ceiling level. The design, fastened by the lower and upper trim, will be strong and durable.

After the frame of the wooden building is ready and reinforced with side trim, it will be time to think about erecting solid walls with windows or installing openwork grilles. The owner may also wish to leave the wall openings completely open. The construction of the summer house also includes floor assembly. There you can place garden furniture, which will give rest comfort. Unfortunately, usually inside such a room is damp enough, which can cause rapid destruction of the tree.

This is a particularly important stage, which will allow the future use of the gazebo with convenience.

This is a particularly important stage, which will allow the future use of the gazebo with convenience.

To lay wooden floors, on the ground under the gazebo as a support you need to put thick boards or beams. Stack them perpendicular to the entrance, parallel to each other. During assembly, special attention is paid to creating a smooth surface, controlling it with a water level. Incorrect work at this stage can lead to a curved coating. After laying, it remains to nail or bolt the floorboards to the lower beams, previously lubricated with an antiseptic.

Did you know? According to archaeological data, the first arbors served as protection from the sun 20 thousand years ago, and they were built on the territory of Ancient Egypt. Large monumental structures of this type appeared a bit later in Ancient Greece and Rome, where they were decorated with expensive marble and granite.

The design does not require the installation of transverse lower beams, if it is planned to manufacture a concrete floor. Cement slabs or pavers may not look as impressive as wood, but they are much more resistant to moisture and do not require maintenance. Due to their unpretentiousness, they are willingly chosen for wooden arbors.

Frame posts

After the foundation is completed, it is time for the installation of the vertical structural supports of the frame. Construction is started only after the cement mortar has completely dried. Supports are bolted to steel anchors protruding from hardened concrete.

During operation, it will be most important to observe angles in the vertical and horizontal plane. All measurements are performed at least twice, which will help ensure the correct profiling of the supporting structure of the building. After installing and fixing the frame with a strapping (upper and lower), you can begin assembling the walls.

Roof system and roof

Summer houses 4 × 4 require the creation of a durable roof, resistant to weather conditions. The roof can be different: classic hipped, single or gable, gabled. Ready-made designs for garden gazebos determine the exact features of the frame structure and the preferred finishing materials. The simplest pitched roof is the easiest to install. Unfortunately, such a solution is at the same time the least elegant, so the choice of form and design specifics should be taken into account before the start of construction, when creating a drawing or considering a finished project.

Did you know? The oldest building made of wood nlocated in Japan — This is the Horyuji Temple. He is about 1400 years old.

The basis of the roof is a wooden frame. On it, the transverse beams are fixed with screws and additional angular struts are installed. Chipboards with a thickness of 2–3.5 cm are laid on top of them. They will become the lower layer of the roof, strengthening the roof supporting structure along the longitudinal slopes. The next step should be the installation of moisture insulation, for example, roofing material or bitumen coating. Also on wooden structures you can use a metal, slate or traditional thatched roof.

The choice of coating depends entirely on what decorative effect the master wants to achieve.

The choice of coating depends entirely on what decorative effect the master wants to achieve.

Walling and cladding

The construction of a closed gazebo ends with the installation of dense, homogeneous or openwork and decorative (wooden gratings) walls. They are made separately in blocks for each side, after which the finished elements are attached directly to the supporting structure.

It is advisable to protect wood for the manufacture of a summer house from damage by impregnation, stain, varnish or oil paint. Transparent varnish is very popular, which emphasizes the structure of the tree and slightly darkens the color of the material. The choice of coverage depends on the taste and preferences of the owner of the plot.

Impregnation and stain penetrate deep into the structure of the tree, protecting it from the inside. They are very effective against pests, but not too good as an obstacle to moisture. In turn, all types of varnishes and oil paints will provide a moisture-proof barrier from the street. The gazebo should be painted (varnished) once every two to three years.

A gazebo is the dream of many people having a house with a garden or a plot. It can become a summer vacation destination for the whole family, protection from the sun and rain, as well as decorating the homestead.