An artificial decorative pond with streams, fountains or waterfalls will effectively complement any landscape composition. In its design, it is desirable to use materials that will ensure the cleanliness of the pond for many years. When arranging artificial reservoirs or strengthening the coastline of existing facilities, various types of geotextiles are used. A large selection of geomaterial contributes to the effective solution of all tasks. About what type of geotextile fabric to choose and how to lay it on the bottom of the reservoir, - later in the article.

What is a geotextile for a pond

The device of an artificial reservoir is associated with the use of a material that prevents the absorption of water by the soil and stabilizes the liquid level throughout the year. The most commonly used polymer membrane, a characteristic feature of which is high sensitivity to mechanical stress. For example, it can be damaged by stones, plant roots.

Did you know? The decorative pond is able not only to give uniqueness to the appearance of the entire plot, but also significantly improve the microclimate of the garden by increasing the level of humidity.

Protect the membrane with geotextile. This is one of the types of geosynthetic technical materials, which is characterized by moisture permeability and strength. It separates the layers of the soil and compensates for the load. Geo-band is placed between the ground and the film. Strengthen the protection by flooring geotextile and over a waterproofing membrane. High elasticity of the geo-sheet allows to withstand a very strong external impact, thereby extending the life of the pond.

Geotextile over the waterproofing membrane promotes uniform distribution of river sand and sea pebbles over the entire surface of the bottom of the reservoir. The roughness of the geo-band will prevent the shift of design elements in one direction after filling the pit with water. The presence of pebbles at the bottom makes it possible in the future to fill the pond with a lot of algae.

The use of a geo-canvas for a pond together with a waterproofing film is acceptable for the arrangement of shallow ponds. When constructing a swimming pool, it is necessary to concrete the pit. When constructing a larger artificial reservoir, it is necessary to level the bottom profile. To do this, pour a thick layer of sand, the so-called cushion pad. Its purpose is to separate the geomembrane from the ground and compensate for the arising load. Geotextiles are used to separate sand from the soil, preventing their mixing over the long life of the reservoir. As a result, the cushioning properties of the pillow are preserved for a long time.

In regions characterized by a large amount of precipitation, the walls of the pond are often eroded from the outside. The properties of the geo sheet allow drainage of the reservoir, i.e., quickly remove moisture to the lower layers of the soil. The walls of the pit can collapse due to dry sandy soil, which often crumbles, as well as under the weight of the waterproofing sheet. Synthetic textiles can prevent this from happening.

Why is geotextile and its properties needed?

Non-woven needle-punched fabric, which is used to shelter plants, is not used in the arrangement of a reservoir, because it is too thin. A geotextile of a different thickness and structure is suitable for a pond. In appearance, it looks like felt. The geo-sheet consists of a greater number of polypropylene fibers firmly bonded to each other by thermal sintering.

Important! Dark-colored geotextiles at the bottom of the pond on top of the waterproofing film prevent water from blooming. This allows you to minimize the number of cleanings of the reservoir.

Thanks to such production technology, the material has the following properties:

- strength, which prevents the possibility of tearing the canvas under water pressure;

- soft structure and elasticity, which allow geotextiles to repeat any relief.

The width of the geotextile roll ranges from 2-6 m. The strip length is the greater, the lower the density of the material.

The width of the geotextile roll ranges from 2-6 m. The strip length is the greater, the lower the density of the material.

The density of the canvas for artificial pond is 150-200 g / m². Such material will provide the ability to filter. Excessively dense textiles, although very durable, are characterized by the rapid filling of small pores with soil microparticles, which negatively affects its drainage function. If there is unstable soil in the area with the possibility of landslides, choose a canvas no thinner than 300 g / m².

Types of geotextiles

Synthetics are classified depending on the raw materials used and production technology. Geofabric is made from polyester and polypropylene. In rare cases, use fiberglass, blended yarn with the inclusion of cotton, wool, viscose. Polymeric fabric is considered more durable, reliable, durable. Thanks to such qualities, it has found application in various fields of construction, during agricultural, geotechnical, landscape works.

Polyester is made from recycled materials, for example, from recycled plastic containers. Short fibers of the fabric are interconnected in layers. The fleecy structure and low strength of the polyester compounds are due to the short length of the filaments — about 5–10 cm. The fabric is dyed in beige, brown, black, and gray.

Polyester is made from recycled materials, for example, from recycled plastic containers. Short fibers of the fabric are interconnected in layers. The fleecy structure and low strength of the polyester compounds are due to the short length of the filaments — about 5–10 cm. The fabric is dyed in beige, brown, black, and gray.

The raw materials for the manufacture of polypropylene geotissue use primary. The high strength of the material is due to the use of continuous filament and reliable connection of the layers. Wetting the fiber does not provoke its delamination. The structure of polypropylene geotextiles is dense and not fleecy. The color of the fabric is white, and only if a protective element from ultraviolet rays is added during the manufacturing process, the fiber acquires a gray tint.

Depending on the manufacturing method, geosynthetics are divided into woven and non-woven. Russian enterprises also produce knitted material, which is notable for its low cost, but it is less popular due to its lower strength.

Did you know? Solar salt ponds are considered to be promising alternative energy equipment: the water in them is heated by mixing the layers under the influence of gravity. They play the role of both solar collectors and heat storage devices.

In the manufacture of woven geotextiles, glass or polyester fibers and the usual method of weaving warp and weft are used. The density of the web depends on the size of the cells. Geotissue is characterized by high tensile strength, so it is often used to erect and reinforce the foundation of runways and highways, as well as retaining walls of bridges. This fiber is not suitable for drainage and filtration.

Low-strength geofabric is used to create elements of landscape compositions, strengthen soil, form flower beds in any territory, even on a slope.

Low-strength geofabric is used to create elements of landscape compositions, strengthen soil, form flower beds in any territory, even on a slope.

Non-woven geo-cloth is made by mechanical or thermal bonding of polymer threads.

Did you know? The most beautiful in the world recognized Japanese pond Biei on about. Hokkaido The color of the water in it changes from deep blue to pale turquoise depending on the angle of view.

Three types of material are distinguished depending on the raw materials used and the production method:

- Needle-punched fabric is manufactured using short and continuous threads. In this case, a press is used, the tips of which, piercing the fiber, penetrate from one layer to another, and dense textile is obtained. It is characterized by an excellent filtering property to pass water both across and along, therefore it is used in drainage works.

- As a result of fusion of polypropylene filaments during heating, a thermally bonded geo-cloth is formed. This method is not acceptable for polyester fibers. They melt at a very high temperature and the proceeds from the sale of the material would not cover the cost of production.

- Hydro-bonded fabric is made of polypropylene fibers, which are affected by thin streams of water under high pressure, without damaging the monofilament.

Domestic construction companies prefer to use thermally bonded geo-cloth, while European ones prefer needle-punched.

Domestic construction companies prefer to use thermally bonded geo-cloth, while European ones prefer needle-punched.

In the West they use the high filtering ability of geotextiles while working on any soil, even on clay. And the low strength of needle-punched geo-cloth is compensated by using a geogrid for reinforcement. Heat-treated material is high-strength, but is able to pass water only across. It is used for soil strengthening due to excellent reinforcing characteristics. A denser geo-band must be used with a high expected load on the coating.

- Geotextiles are often used to equip artificial reservoirs due to its advantages:

- Low cost, which is due to cheap raw materials, a simple process. The price of the geo-band varies between 15–25 rubles. for 1 m². The use of cheap material helps to reduce the costs of other building materials, as a result, the cost of installation works is reduced.

- Safety. When operating polyester and polypropylene geofibers, toxic substances are not released. The environment does not suffer from the production process.

- Durability. Geo-canvas, especially polypropylene, tolerates the effects of acids, alkalis and other hazardous substances contained in land and water. Polymer threads do not rot. They are not damaged by water, low temperatures, heat, the sun. The life of geotextiles is shortened only due to the gradual filling of pores with fine particles of soil. As a result, after some time, the fabric does not perform the filtering function. The durability of the material is affected by its technical characteristics. The life of high-quality textiles is approximately 30 years.

- Strength. Geo-band resistant to stretching both across and along. The most durable is textile based on monofilament made of polypropylene. This property of the canvas is used to strengthen the foundations of structures with high load.

- Versatility. The use of the canvas is very diverse due to such useful properties as strength, elasticity, water permeability, resistance to hazardous substances.

- Easy styling. No special skills are required to lay the geofence. Outlets offer it in a roll, which is convenient for transportation. Textiles have a small mass, it is easily cut with ordinary scissors.

How to lay on the bottom of an artificial reservoir

Immediately after completion of the excavation, you should begin laying geotextiles. It is difficult to calculate the exact amount of canvas. It is preferable to make a purchase after the preparatory work. First, measure the maximum width and length of the pond with a skein of twine. To do this, put the braid on the surface of the pit.

Important! When buying a geo-canvas for the construction of an artificial reservoir, it is necessary to take into account the additional distance for overlapping in the calculations.

Before laying the geo-canvas on the bottom of the reservoir, carry out preparatory measures:

- get rid of all small, large and sharp stones so that they do not damage the fabric;

- level the bottom with a layer of sand and soil mixture and compact it.

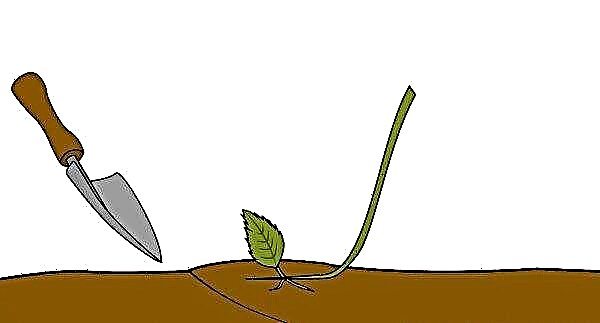

Then rolls of geotissue should be rolled out and cut into strips. Please note that the canvas is overlapped. To achieve the greatest efficiency, a grip of about 15–20 cm is used. This technique allows the canvas not to scatter apart under the weight of water. Begin to lay special geotextile material from the center.

For this work it is necessary to involve three people:

- Two of them should take a strip on both sides and cover the foundation pit from above so that the center of the canvas covers the middle of the bottom of the pit.

- Then another assistant should stand on the fabric while loosening the sleeves.

- Further, the strip is carefully laid from the center to the shore of the reservoir.

- Then they lay the next overlap.

When laying, the geotextile acquires the shape of the relief of the bottom of the reservoir, therefore it is not necessary to align it additionally. It is necessary to leave an allowance of about 60 cm in order to equip the coastline of the pond. A geomembrane is laid on top of the geotissue.

When laying, the geotextile acquires the shape of the relief of the bottom of the reservoir, therefore it is not necessary to align it additionally. It is necessary to leave an allowance of about 60 cm in order to equip the coastline of the pond. A geomembrane is laid on top of the geotissue.

When constructing a reservoir, do not neglect geotextiles - technical, practical and cheap synthetics. Geopolotically evenly distributes the load on the soil and reduces the likelihood of displacement, subsidence, deformation of the soil, protects the geomembrane from damage, prevents the accumulation of sand and pebbles in one place. It extends the period of operation of the pond and reduces the cost of its arrangement. It is desirable to choose the density of the geo-cloth, taking into account the terrain. When purchasing geosynthetics, pay attention to the presence of quality certificates, certificates of conformity and the guarantees provided for the goods.